GROUND ANCHORS & PASSIVE TIES

Piletec can offer post-stressed ground anchors where accurate lock off forces are required. However, often a simpler, quicker and more cost effective passive tie option can be provided. Passive ties are generally the optimum solution in more competent strata, and where a small amount of movement can be accommodated to generate the required restraining forces. Ground anchors are constructed using strand or bar, whereas passive ties are formed using bar.

TYPES OF GROUND ANCHORS

Advantages

- Each anchor is customised to suit loading and lengths

- Easy storage and assembly due to coiled reels

- Easy installation even in tight spaces

- No coupler splices

- Guaranteed higher safety factor due to multiple tension elements in each anchor

- Corrosion protection fabricated in shop

- Anchors can be re stressed for testing during service life

- Anchors can be outfitted with instrumentation for real time monitoring during service life

Advantages

- Lower grade bars ideal for soil nailing, micro piles and passive anchors, when open holes can be drilled.

- Mid grade bar ideal for tower crane bases, turbines.

- Corrosion protection is fabricated and applied in shop.

Applications:

Solid bar anchors are typically used with excavation shoring, and retaining walls.

Advantages

- Fast one-step installation

- Simultaneous drilling and grouting

- Allows the use of smaller equipment at lower cost

- Allows low overhead, limited access installation

- Improves the ground (densification)

- Offers higher skin friction

- Total single corrosion protection by design

Applications

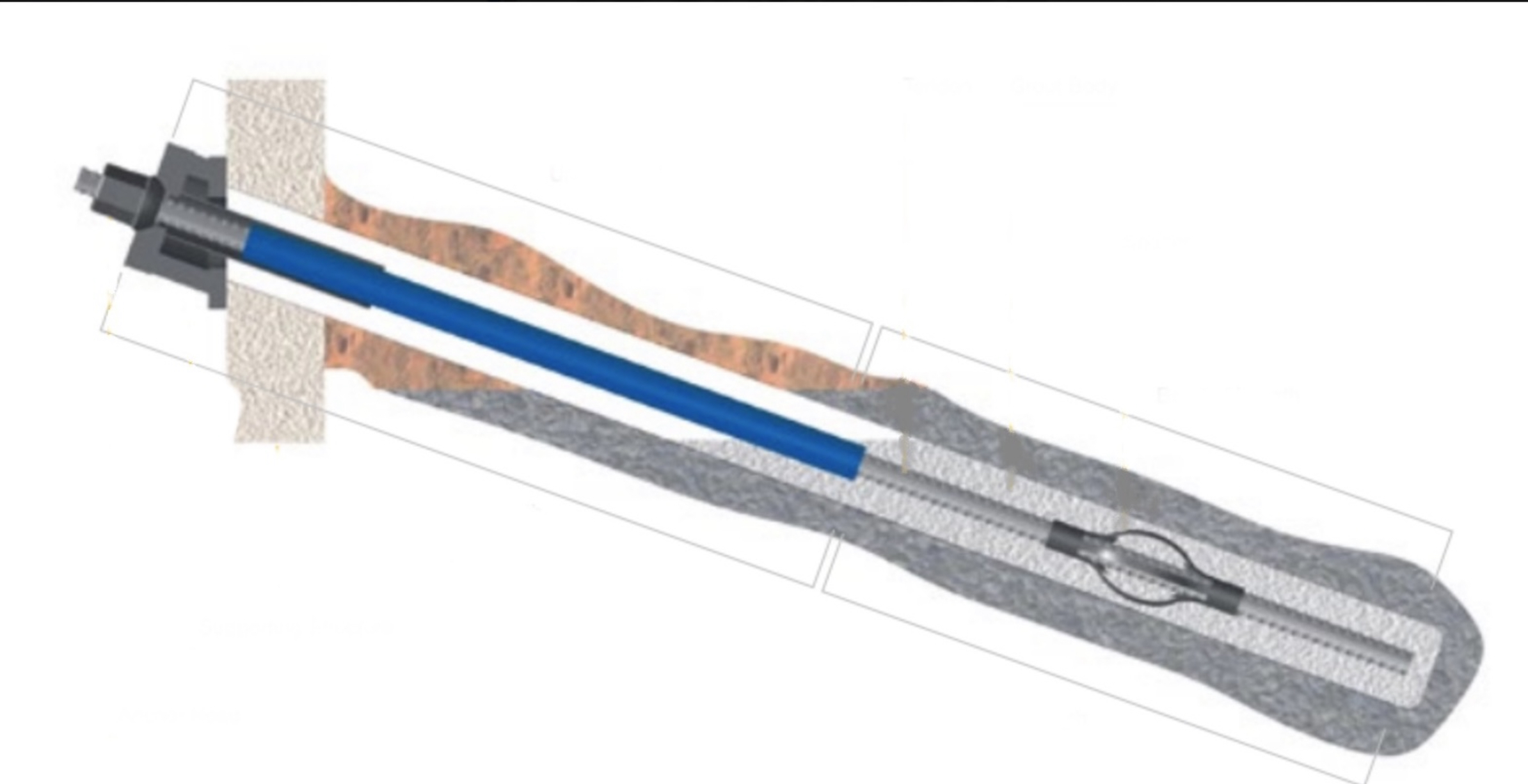

Hollow bar anchors are ideal for soil nails, micro piles, and anchors in difficult ground conditions like weathered and decomposed rock, sand and clay soils for either permanent or temporary applications.

Advantages

- Standard lightweight equipment

- Quick and easy installation

- Environmentally friendly

- Immediately ready for use

- Wide range of applications

- Marine Applications

- Retaining Walls

- Slope Stabilisation

- Temporary Works

- Tie Backs

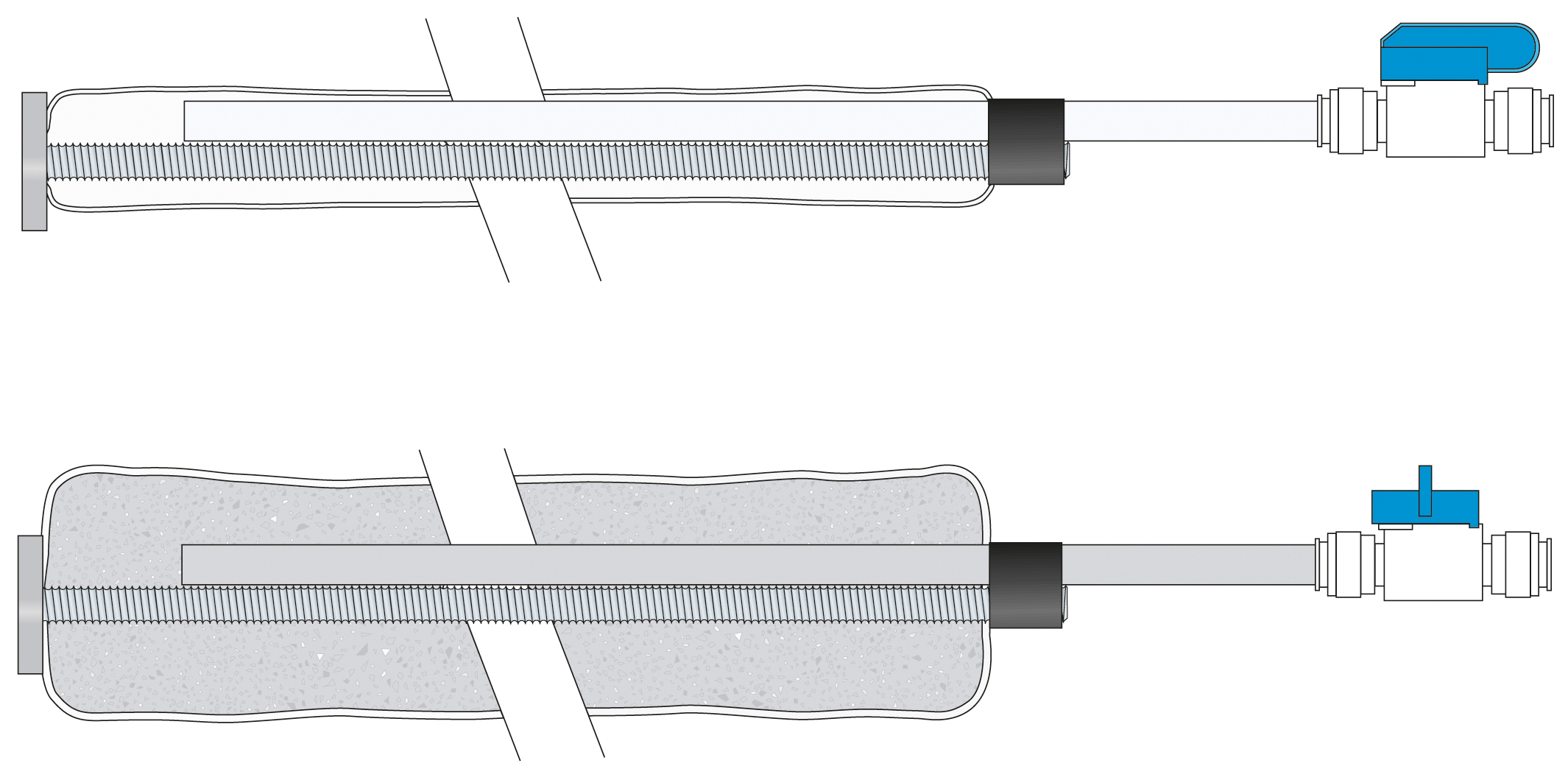

Advantages

- Simple installation

- Saves on grout and other materials

- High strength

- Made to any length

- Available to fit up to 90mm core hole

- Testing plant readily available

- Offers anchorage into rock Applications

Grout-filled sock combines with threaded bar in a composite action and expands to form a strong chemical/mechanical bond with the substrate

- For heavy duty, high load, applications

- For stitching cracked solid and multi-leaf walls

- For stabilising rubble-filled walls

- For securing unstable parapet walls and arches

- Where high levels of performance are required in bending

- Where drilling lengths in excess of 1m are required