PILETEC'S PILING SERVICES

We specialise in:

– Continuous Flight Auger (CFA) Piling – Efficient, adaptable, and suitable for various soil conditions.

– Sectional Flight Auger (SFA) Piling – Perfect for restricted access or confined spaces.

– Rotary Open Bore Piling – Designed for challenging and variable terrains.

– Overburden Systems – Ideal for layered or obstructed ground conditions.

– Grundomat Piling – A versatile option for tight, complex environments.

Using cutting-edge equipment and precise execution, we ensure every project is completed safely, efficiently, and to the highest standards, building dependable foundations for lasting success.

TYPES OF PILING

Sectional flight auger

450mm Rock Drilling

Low Headroom 450mm Contiguous Piled Wall

To ensure successful installation, the soil must be stable enough to retain the borehole’s shape during drilling and concrete placement. Rotary Open Bored Piles are less suitable for areas with groundwater unless effective dewatering can be carried out and concrete can be placed without requiring a permanent casing.

These piles are ideal for projects requiring a cost-effective and reliable foundation solution, provided the ground conditions align with the method’s requirements.

A limitation of pre-drilling is that the bearing capacity of the pile may be reduced due to decompression. This aspect must be taken into consideration when the load carrying capacity of the pile is estimated.

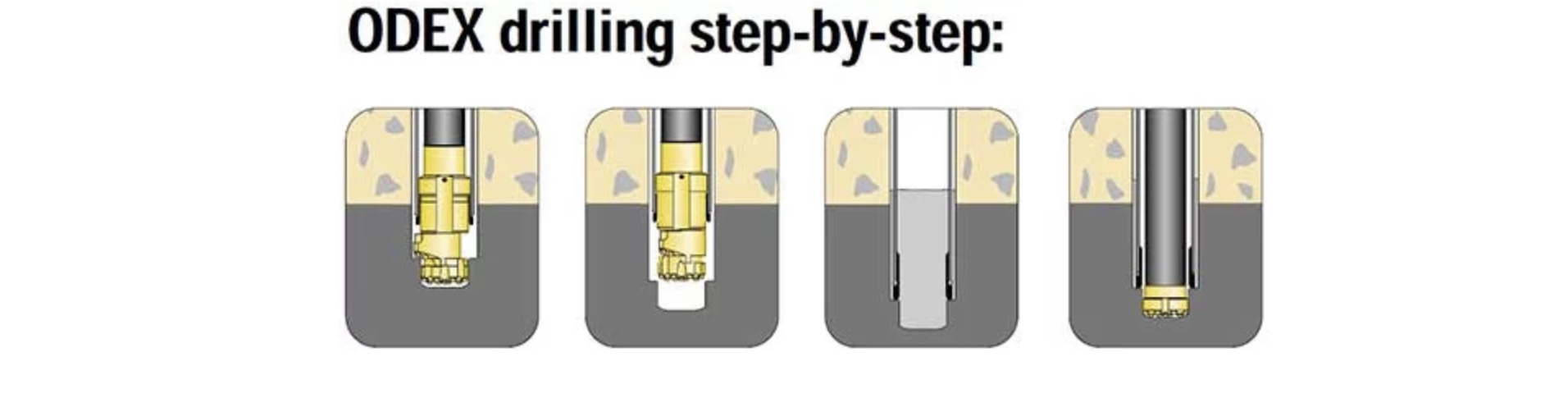

Odex Piling

Super Jaws

Designed for top performance in both overburden and solid rock formations.

Large bit face area for transferring blow energy to the formation yielding faster penetration rates.

Uniquely designed bit wings extend out further than the casing O.D. when the bit reaches bottom to allow simultaneous drilling and casing.

The bit can be used to the full operating pressure of the hammer resulting in rapid penetration and minimum drilling time.

Bit wings retract inside the casing when the hammer is pulled off bottom. No reverse rotation, which can cause unscrewing, is required.

No ring bits or other drilling equipment is left down the hole.

The flexibility of Grundomat driven piles lies in the fact that they can be used where other pile driving solutions simply cannot. Restricted access needn’t be a problem and this means that driven piles can be added in extremely hard to reach situations while still only requiring a small pile driving team consisting of 2 people.

The minimal vibrations and low noise mean that they can even be used in residential areas for the construction of extensions and conservatories on residential properties. Grundomat piles are also widely used on the railway infrastructure

The rotary percussive drilling method ensures minimal disturbance is caused during installation compared to driven piling systems, enabling the foundations of old structures or buildings to be upgraded without damage. Pile stiffness can be increased by placing a steel tube over the top 2m of bar and grouting the annulus.